Steel Wire Armoured GYTA33 Optical Fibre Cable

Model No.︰GYTA33

Brand Name︰Surelink

Country of Origin︰China

Unit Price︰US $ 1 / meter

Minimum Order︰3000 meter

Product Description

Surelink steel wire armoured OPTICAL FIBER CABLE GYTA33 SM 24 FIBERS

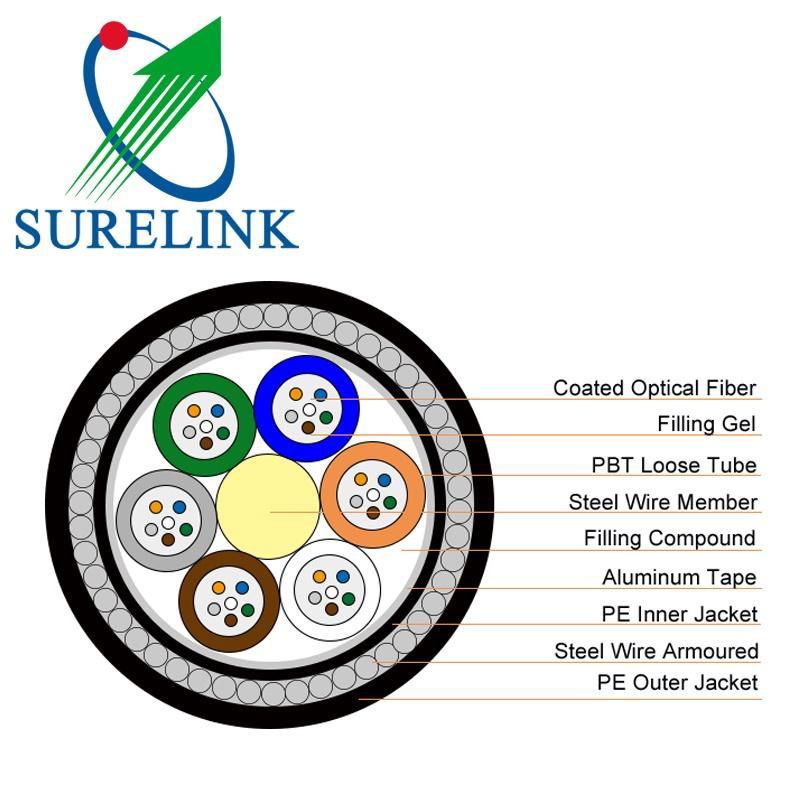

| Cable Structure |

| Technical Parameters |

Cable structure and parameter

| Fiber

count |

Max. fiber

count per tube |

Total unit

count (LT + FR) |

Steel wire for

armoring |

Sheath

thickness (nominal*) |

Overall diameter

(nominal**) |

Weight

(approx.) |

| i/o mm | mm | kg/km | ||||

| 24 | 6 | 4LT+2FR | 1.2mm*26 | 1.0/1.6 | 14.7 | 381 |

* The nominal sheath thickness may have a tolerance with ±0.2mm.

* * The nominal overall diameter may have a tolerance with ±0.2mm.

Performance of Cabled Optical Fiber

The performance of cabled optical fiber (ITU-T Rec. G.652D)

| Item | Specification |

| Fiber type | Single mode |

| Fiber material | Doped silica |

| Attenuation coefficient

@ 1310 nm @ 1383 nm @ 1550 nm @ 1625 nm |

≤ 0.35 dB/km ≤ 0.35 dB/km ≤ 0.21 dB/km ≤ 0.30 dB/km |

| Point discontinuity | ≤ 0.05 dB |

| Cable cut-off wavelength | ≤ 1260 nm |

| Zero-dispersion wavelength | 1300 ~ 1324 nm |

| Zero-dispersion slope | ≤ 0.093 ps/(nm².km) |

| Chromatic dispersion

@ 1288 ~ 1339 nm @ 1271 ~ 1360 nm @ 1550 nm @ 1625 nm |

≤3.5 ps/(nm. km) ≤5.3 ps/(nm. km) ≤18 ps/(nm. km) ≤22 ps/(nm. km) |

| PMDQ (Quadrature average*) | ≤0.2 ps/km½ |

| Mode field diameter @ 1310 nm | (8.6~9.5)±0.6 um |

| Core / Clad concentricity error | ≤ 0.6 um |

| Cladding diameter | 125.0 ± 1 um |

| Cladding non-circularity | ≤1.0% |

| Primary coating diameter | 245 ± 10 um |

| Proof test level | 100 kpsi (=0.69 Gpa), 1% |

| Temperature dependence

0℃~ +70℃ @ 1310 & 1550nm |

≤0.1 dB/km |

Cable bending radius: 10 x cable diameter (static)

15 x cable diameter (dynamic)

Application temperature range

| Operating temperature range | -40oC to +60oC |

| Storage / Transport temperature range | -50oC to +70oC |

| Installation temperature range | -20oC to +50oC |

Main mechanical & environmental performance test

| S/N | Item | Test Method | Acceptance Condition |

| 1 | Tensile Strength

IEC 794-1-E1 |

- Load: 3,000N

50 m -Load time:≥1min. |

- Loss change ≤ 0.1 dB @1550 nm

- No fiber break and no sheath damage. |

| 2 | Crush Test

IEC 794-1-E3 |

- Load: 4,000 N/100 mm

- Load time: ≥1min. |

- Loss change ≤ 0.1 dB @1550 nm

- No fiber break and no sheath damage. |

| 3 | Impact Resistance

IEC 794-1-E4 |

- Points of impact: 5

12.5mm

|

- Loss change ≤ 0.1 dB @1550 nm

- No fiber break and no sheath damage. |

| 4 | Repeated Bending

IEC 794-1-E6 |

- Bending radius: 20 x cable diameter

|

- Loss change ≤ 0.1 dB @1550 nm

- No fiber break and no sheath damage. |

| 5 |

Water Penetration Test

|

- Height of water: 1 m

- Sample length: 3 m - Test time: 24 hours |

- No water shall have leaked from the

opposite end of cable. |

| 6 |

Temperature Cycling Test

|

- Temperature step:

+20℃→-40℃→+60℃→+20℃ - Time per each step: 24 hrs - Number of cycle: 2 |

- Loss change ≤ 0.05 dB/km@1550 nm

- No fiber break and no sheath damage. |

| 7 | Compound Flow

IEC 794-1-E14 |

- Sample length: 30 cm

- Temp: 70°C ± 2°C - Time: 24 hours |

- No compound flow |

Packing

Each single cable length been wound on an iron stand-wooden composite or pure wooden drum.

Standard drum length is 2000m ±2%, or it can be delivered as customer requirement but not longer than 6000m with a tolerance.

Covered by plastic buffer sheet.

Sealed by strong wooden battens.

At least 1m of cable inner end should be reserved for testing.

| Related Package |

Package Details:

Iron-wooden drum or fumugated wooden drum,normal wooden drum

Drum size can be designed,details will calculation for suitable for containers

| Related Hot Models |

| Manufacturer Introduction |

Zhuhai Surelink Communication Cable Co.,Ltd is one of the leading manufacturer in the cables and telecom accessories. We have more than 20 years experience in this line.Our factory has over twenty production lines and 300 employees.

Our productions comply with ISO9001.Professional team,powerful factory and strict quality control give

best service to our clients and the quality guarantee in every order.

Our products have been widely installed in Telecom companies and many distributors around the world.

We export to more than 70 countries and our annual revenue is more than hundreds of million USD.

We have established a close relationship with many companies around the world and we sincerely look forward to woking with all clients from all over the world.

OEM and ODM order highly welcome !

| Company Show |

| Certificate |

| Workshop and Quality Test |

| Package and Delivery |

| Payment and Shipping |

Payment

We usually use T/T

T/T deposit before production and balance when shipment.

Payment terms: Western Union, Escrow, Paypal, T/T ,L/C

Shipping

If the quantity of the order is not very big, we usually send by express delivery,such as TNT,DHL,UPS,FEDEX or EMS.

For big order,we will ship the goods by air or by sea.

| Just Talk To Us! |